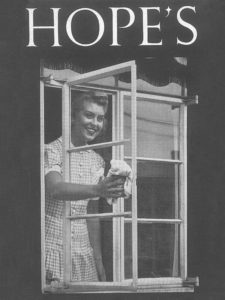

HOPE’S HISTORY

Over a century of handcrafted excellence.

Throughout its long history, Hope’s steel windows and doors have been synonymous with longevity and quality. From the development of truly visionary design concepts through an unparalleled finishing process, Hope’s is the first choice in premium quality steel and bronze windows and doors.

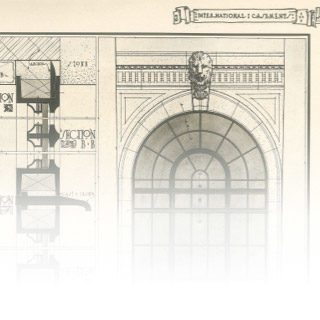

1912

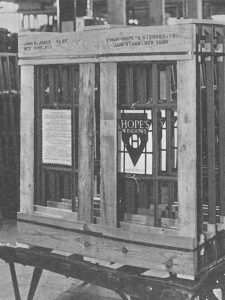

Hope’s Windows was founded in Jamestown, New York and was originally known as International Casement Company, Inc.

Company founder, Mr. Thomas Ringrose of England, came to the United States with more than 10 years of casement window design and manufacturing experience to explore the potential for selling steel windows. He essentially created a new industry in the U.S. with the incorporation of International Casement Co.

Business was commenced in a rented factory with seven employees and was successful from the start. International Casement Company’s first order was to furnish steel windows for the Prudence Risley Hall at Cornell University.

The company was able to buy land and build a factory on Hopkins Avenue, Jamestown, now known as Hope’s Plant 1. Ten years later the majority of the common stock of the company was acquired by Henry Hope & Sons, Limited.

1916

1926

Mr. Ringrose was succeeded in Jamestown by Mr. Frank Garratt, then sales manager for Hope’s.

International Casement merged with the importing business of Henry Hope & Sons, Inc. of New York to become Hope’s Windows, Inc. The company continued to manufacture and sell steel window products, including the sale of products manufactured by Henry Hope & Sons, Ltd.

1932

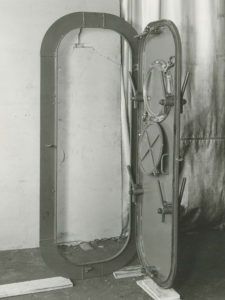

During World War II, Hope’s normal business was halted and its factories were equipped to manufacture products needed for the war effort. For four years Hope’s manufactured a variety of marine equipment in steel, aluminum, and bronze and in October 1944 it was awarded the Army-Navy ‘E’ for outstanding production of materials for war.

1941

1969

The mid-20th century was a tumultuous time for American steel. Despite several mergers and acquisitions at the corporate level, Hope’s Windows continued the businesss of manufacturing and selling steel windows under the Hope’s® tradename and trademark.

In 1969, Hope’s Windows merged with three other corporations and was known as Roblin Hope’s Industries, Inc. Roblin Hopes continued to manufacture and sell steel windows under the Hope’s trademark.

Roblin Hope’s merged into Roblin Industries with Hope’s Windows continuing to operate as a division of Roblin Industries, Inc.

1975

1982

Mr. Frank A. Farrell, Jr. formed Hope’s Architectural products, Inc. and acquired all of the assets and business of the Hope’s Windows division from Roblin Industries. Hope’s Architectural continued to manufacture steel window products from the same manufacturing facility in Jamestown where the company began in 1912. In 1998, Hope’s Architectural changed its name back to Hope’s Windows, Inc.

Today

Hope’s is the largest steel window manufacturer in the world with over 230 employees, five manufacturing plants, and a dedicated testing and R&D facility on our Jamestown campus.