Hope’s Windows

Custom Window & Door Products

Explore Hope’s in detail and you will quickly discover unmatched durability and longevity, a quality of refined elegance impossible to achieve with other materials, and a new level of freedom to design and build custom windows and doors of steel and bronze. Hope’s incomparable product offerings include the following:

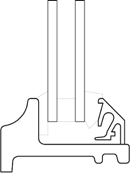

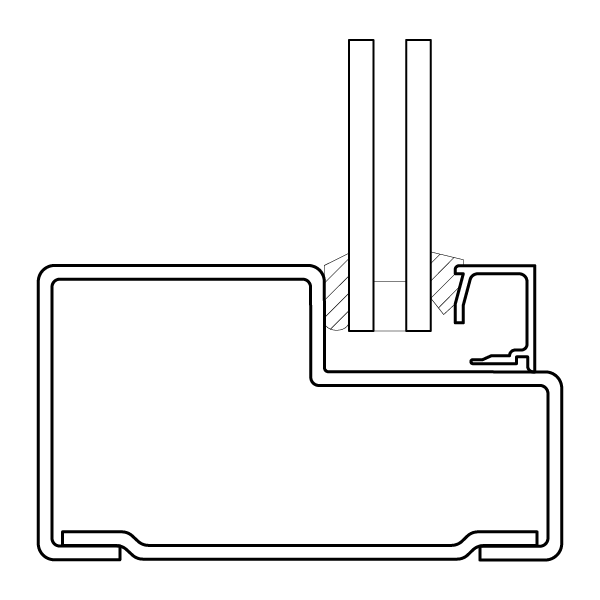

Jamestown175™ Series

Ideal for projects requiring oversize windows and doors with narrow sightlines. This series offers special operating types such as top hung or pivoting windows and is certified for use in special applications such as hurricane resistance.

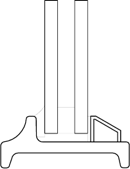

Landmark175™ Series

Ideal for projects calling for classic solid steel windows and doors with slender sightlines. This series offers an even narrower sightline for operable windows and doors than our Jamestown175 Series.

Old World Suite™

Designed for projects calling for classic solid steel windows and doors with old world style three-point casement, or arrow-shaped, profiles. This distinctive profile with its very narrow framing mimics the old world style of the earliest steel windows.

One55™ Series

Designed for projects requiring replication of historic steel windows and doors with arrow-shaped profiles. This distinctive profile with its very narrow framing mimics the look of the earliest residential steel windows and historic industrial designs.

University Series™

Designed for projects requiring historic replication of exterior putty-glazed steel windows and doors. The unique profile and narrow sightlines are ideal for new construction as well as replacement projects.

Empire Bronze™ Jamestown175™ Series

Offers the ageless beauty of solid bronze with the elegant sightlines, durability, and meticulous manufacturing techniques synonymous with all Hope’s products.

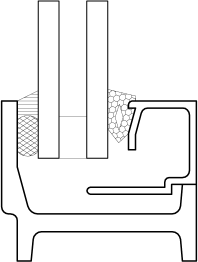

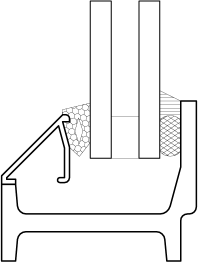

5000 Series™

Ideal for special operations such as pivot, lift-slide, or slide-fold. These windows, doors, and skylights are custom formed from heavy gauge steel and complement Hope’s traditional hot-rolled steel products by providing the greatest latitude for design flexibility and hardware options.

Empire Bronze™ 5000 Series™

These windows, doors, and skylights are custom formed from heavy gauge bronze and complement our traditional hot-rolled bronze products by providing the greatest latitude for design flexibility and hardware options.

Our Products By Function:

WIndows

Doors

Skylights