Thermal Steel Windows

Solid, Hot-rolled Steel Windows and Doors with a Thermal Break

Experience the Evolution of Thermal Efficiency in Solid Steel

Steel is five times more thermal resistant than aluminum, making it the ideal material for constructing the longest-lasting and best performing windows and doors. With Hope’s exclusive Thermal Evolution™ technology, all the intrinsic strengths of solid hot-rolled steel are maintained along with enhanced thermal efficiency, exceeding today’s most stringent thermal codes.

Operable Landmark175™ Series solid steel window with Thermal Evolution technology.

Fixed Landmark175™ Series solid steel window with Thermal Evolution technology.

Our Products By Project Type:

- Residential Steel & Bronze Windows & Doors

- Commercial Steel & Bronze Windows & Doors

- Historic Steel Window Replacement

- Interior Steel & Bronze Windows, Doors & Partitions

- Thermal Steel Windows

- Hurricane and Impact Rated Steel & Bronze Windows & Doors

- Blast, Bullet, and Fire Rated Steel Windows and Doors

- Residential Steel & Bronze Windows & Doors

- Commercial Steel & Bronze Windows & Doors

- Historic Steel Window Replacement

- Interior Steel & Bronze Windows, Doors & Partitions

- Thermal Steel Windows

- Hurricane and Impact Rated Steel & Bronze Windows & Doors

- Blast, Bullet, and Fire Rated Steel Windows and Doors

Thermal Evolution Technology:Simply a Superior Solution

Hope’s Thermal Evolution technology is a superior approach for creating a thermal break in fixed and operable time-tested solid hot-rolled steel windows and doors.

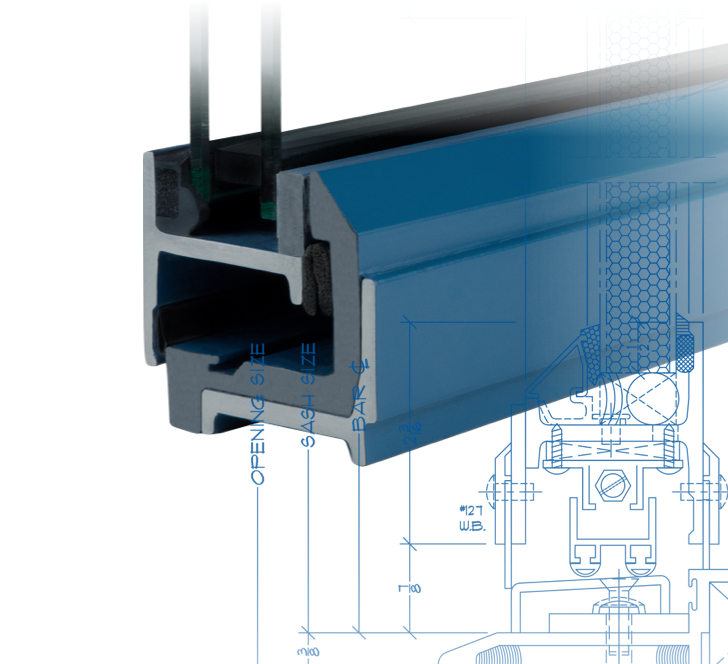

A Hope’s window or door equipped with Thermal Evolution technology features a fiber-reinforced polymer (FRP) isolator that is precision-machined to nest perfectly within Hope’s traditional hot-rolled solid steel frame profiles. This highly thermally resistant FRP isolator is structurally bonded to Hope’s steel window and door frames to create a powerfully strong and enduring composite construction that delivers impressive thermal efficiency and enhanced resistance to condensation.

Operable portion of window made from solid hot-rolled steel

To thermally isolate steel, the fixed portion of the window includes a precision-machined FRP isolator structurally bonded to solid hot-rolled steel

Solid hot-rolled steel

All the Aesthetic and Structural Benefits of Solid Hot-Rolled Steel Maintained

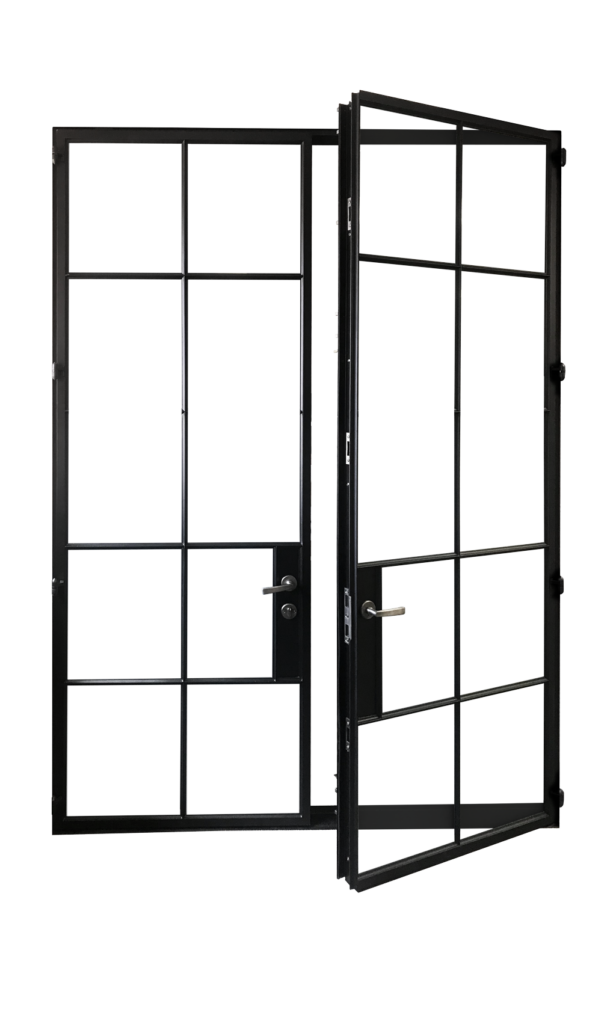

With our patented Thermal Evolution technology, Hope’s is the only manufacturer of solid hot-rolled steel windows and doors with a thermal break. This means all the exquisite aesthetic potential of steel is maintained, including structural strength for virtually unlimited window size, extremely narrow frame dimensions and maximum glass area for the ultimate in clear views.

Hope’s windows and doors equipped with Thermal Evolution technology are ideal for new or retrofit construction of luxury residential, high-end commercial, cultural, institutional and historic preservation applications in virtually any color you can imagine.

Thermal Evolution technology accommodates True Divided Lite (TDL) or Simulated Divided Lite (SDL) muntin systems. Hope’s Power of 5 Finishing System ensures that all Hope’s steel windows and doors last longer than any other available, even under the most extreme environmental conditions.

Product Performance

- Meets or exceeds forced entry test criteria in accordance with ASTM F588

- Meets or exceeds air infiltration test criteria in accordance with ASTM E283

- Meets or exceeds water penetration test criteria in accordance with ASTM E331

- Meets or exceeds structural test in accordance with ASTM E330

- Thermal tested, listed, and certified in accordance with NFRC-100, NFRC-200, and NFRC-500

Refer to product specific specifications for design performance data.

NFRC Certified

The National Fenestration Rating Council® (NFRC), the U.S. leader in energy performance rating and certification programs for the window and door industry, ensures consistent third-party testing criteria with public access to product testing results.

Hope’s Landmark175™ Series with Thermal Evolution technology achieved impressive testing results from NFRC:

| U-factor as low as: | CR rating as high as: | |

|---|---|---|

| Fixed Windows | 0.17 | 49 |

| Operable Windows | 0.24 | 36 |

| Doors | 0.26 | 37 |

| Thermal tested, listed, and certified in accordance with NFRC-100, NFRC-200, and NFRC-300. U-value is a measure of heat loss with lower numbers indicating better insulating properties. CR is a measure of condensation resistance with higher numbers representing more resistance to the formation of condensation. | ||

It is also important to understand that thermal performance varies depending upon glass make-up and other variables of a window. For example, triple-paned windows will produce an even better U-factor than traditional single pane of glass.

Download Specifications

It is also important to understand that thermal performance varies depending upon glass make-up and other variables of a window. For example, triple-paned windows will produce an even better U-factor than traditional single pane of glass.

Specifications for products with Thermal Evolution™ Technology:

- Landmark175 Series / Thermal Evolution

- One55 Series / Thermal Evolution

- SlightLine175 Series / Thermal Evolution (COMING SOON)

Thermal Technology Can Be Applied To The Following Product Lines

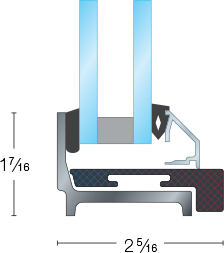

Landmark175 Series with Thermal Evolution Technology

Sightlines

Fixed: 1-7/16”

Operable: 2-3/16”

Section depth: 2-5/16”

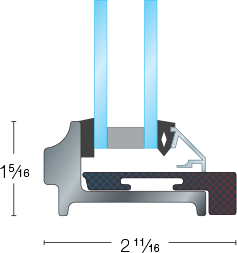

Old World Suite with Thermal Evolution Technology

Sightlines

Fixed: 1-5/16”

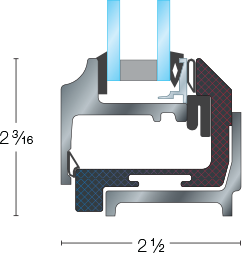

Operable: 2-3/16”

Section depth: 2-1/2”

SlightLine175 with Thermal Evolution Technology

Sightlines

Fixed: 1-7/16”

Operable: 2-3/16”

Section depth: 1-3/4”