Why Choose Steel Windows and Doors?

Hope’s Solid hot-rolled steel offers the slimmest sightlines and unmatched strength; ideal for historic window replication, luxury residential, and commercial applications..

For more than 150 years, windows and doors have been crafted from solid hot-rolled steel. Many of our nation’s historic buildings and mansions dating from the Civil War era and earlier feature these handcrafted materials. Today, it is common for new homes and structures to utilize wood or aluminum windows and doors, not because these materials are superior or even comparable – they’re simply less expensive.

Join us for a look at what makes Hope’s solid, hot-rolled steel windows and doors the best long-term investment for your property.

The Material Difference

UNMATCHED STRENGTH & MINIMAL SIGHTLINES

Solid Hot-Rolled Steel

What makes solid, hot-rolled steel a superior material? For starters, it is three times stronger than aluminum and sixteen times stronger than wood. This strength allows Hope’s to make windows and doors with the slimmest frames, the greatest amount of glass, and in virtually unlimited scale, shapes, and configurations.

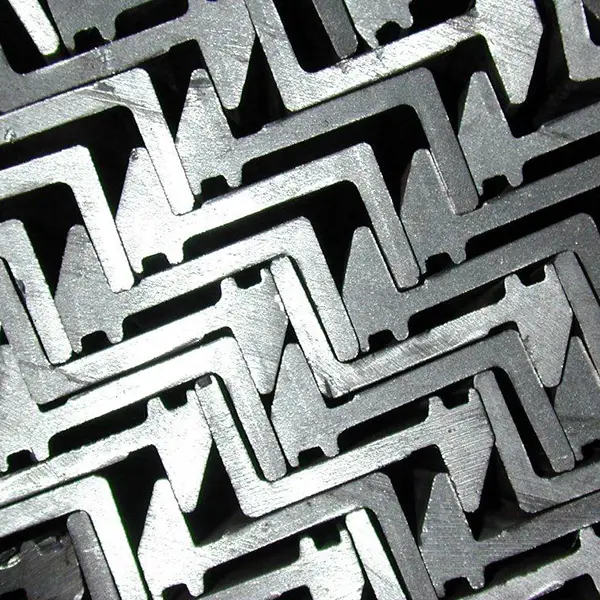

Custom-Formed Steel

Slender • Elegant • Refined • Minimalist

NARROW SIGHTLINES

These words often describe the unique look of Hope’s windows and doors. The narrow and graceful lines belie their formidable strength and ultimate durability. Hope’s windows and doors are timeless in appearance and endure for generations.

FRAME DIMENSIONS BY MATERIAL

Owing to the inherent strength of solid, hot-rolled steel, the extremely narrow frame dimensions maximize glass area.

SIGHTLINE – WIDTH AND DEPTH

When choosing windows and doors, it is important to consider the entire field of vision by evaluating both the width and depth of a frame. Windows with a shallower depth let you see more when viewing at an angle than those with a deeper depth.

Custom Choices at Every Phase of Design

DESIGN FLEXIBILITY

Every Hope’s window and door is custom designed by you – the architect, designer, and homeowner – to achieve your specific aesthetic and performance criteria.

HELPFUL AND COMPREHENSIVE DESIGN ASSISTANCE

Hope’s helps guide you along the way to ensure your vision is achieved. Hope’s has earned a reputation for continuously achieving new possibilities in window and door design. Offering more interesting forms and the grandest scales and with more dynamic functionality, no design is too ambitious for Hope’s.

ANY SCALE IMAGINABLE

Whether new construction, remodel, retrofit, or historic preservation, architects and designers incorporate Hope’s windows, skylights, and doors into every variety of architectural style from grand renaissance and gothic revival to imaginative avant-garde and postmodern luxury homes.

BEAUTIFUL, LONG-LASTING FINISHES

To achieve the longest life cycle potential for Hope’s steel windows and doors, Hope’s provides the world’s most advanced finishing system available. Developed in cooperation with top U.S. metallurgists and architectural coatings suppliers, Hope’s Power of 5™ finishing system in engineered to ensure that windows and doors remain pristine and free from corrosion decade after decade, even in the harshest of environments.

For the top coat there are unlimited color choices, including metallics and patinas. You can also work with Hope’s to create a custom color to perfectly integrate with your design.

Soaring windows and wide open doors

MONUMENTAL SIZES

Hope’s solid, extruded architectural bronze frame profiles can sustain the load requirements and achieve the exact aesthtics desired for immense openings, even in areas with the most strict building codes and environmental considerations such as High Velocity Hurricane Zones (HVHZ).

Historically accurate profiles and sightlines with modern efficiencies

HISTORIC REPLICATION

Hope’s partners with historic and landmark preservation committees to maintain the traditional aesthetic of historic buildings while upgrading performance and efficiency to modern standards. Hope’s offers specially designed solid steel profiles along with unique glazing beads and muntin bars to replicate early steel window visual elements such as putty glazing and historic sightlines.

Retrofit and historic renovation projects benefit from over a century of manufacturing and technical advancements – insulated and low-E glass, integral groove weatherstripping to name a few – coupled with slim, historically accurate sightlines. Modern safety features such as hurricane resistance can be incorporated into steel window systems and simultaneously complement the visual integrity of period buildings.

Case Studies:

Optimal thermal performance

ENERGY EFFICIENCY

The intrinsic properties of Hope’s solid, hot-rolled steel windows and doors provide optimal thermal performance. The raw material conducts heat and cold at one-fifth the rate of aluminum substrates. Aluminum products require a thermal break just to match the natural thermal performance of steel. The minimal frame dimensions of steel windows and doors further lesson thermal transfer by reducing surface exposure.

In addition, Hope’s has developed Thermal Evolution™ technology. This advanced thermal-break technology provides exceptional thermal performance and condensation resistance without splitting the steel frame, thus maintaining the proven structural integrity of solid, hot-rolled steel windows and doors. Hope’s exclusive patented Thermal Evolution technology is third-party tested and NFRC certified.

Our windows are independently certified by the National Fenestration Rating Council (NFRC) for U-value and condensation resistance.

The lasting beauty of superior finishes

MINIMAL MAINTENANCE

Every Hope’s custom crafted window and door is built to last several generations with minimal maintenance.

Hope’s low-maintenance protective coating and finishing system provides incomparable long-term protection against corrosion and abrasion whether your building is inland or oceanfront.

Hope’s Power of 5™ Finishing System exceeds the most rigorous testing standards and is carefully scrutinized to ensure products will perform, both aesthetically and functionally, for decades to come.

Efficient manufacturing and eco-friendly products

ENVIRONMENTAL RESPONSIBILITY

Hope’s manufactures windows and doors that are energy efficient and impervious to air and water infiltration, crafted from recycled steel, and finished with environmentally friendly coatings. Hope’s strong and durable windows and doors achieve unparalleled life cycle value. Hope’s will also assist building owners and architects seeking LEED® certification from the U.S. Green Building Council.

Windows and doors that last a lifetime and beyond

LONGEVITY AND LIFE CYCLE

Hope’s is committed to crafting window and doors only from materials with proven ability to last for a century or longer, while providing timeless aesthetic appeal. It is not uncommon for Hope’s steel windows and doors to outlast the buildings in which they are installed. Compare this long life cycle to alternatives such as wood and aluminum, and it’s clear that Hope’s is the best long-term investment both environmentally and financially.

Excellence you should expect

PROVEN PERFORMANCE

Hope’s custom crafted windows and doors set the standard for performance excellence. Hope’s prides itself on its long-standing commitment to testing and certification, subjecting its products to more third-party testing and certifications than any other steel window and door manufacturer. The process of exceeding both rigorous, independent testing and custom expectations begins with the engineering and design of Hope’s products – expertise derived from more than 100 years of experience.

Hope’s has revolutionized windows and doors again by innovating the world’s first and only thermally broken solid, hot-rolled steel window and door systems.

Through decades of research, development and testing, Hope’s Windows, Inc. has worked to perfect the handcrafted artistry of hot-rolled steel windows and doors.

Hope’s takes tremendous pride in offering the ultimate finishing solutions geared to protect your investment whether your project is inland or oceanfront.

Hope’s custom-crafted windows and doors set the standard for performance excellence that no other steel manufacturer has equaled